FINDING THE SPARK

July 20, 2020

A spark plug is an integral part of any internal combustion engine. Put simply, the Fuel/air mixture is drawn into and compressed by the engine and then ignited by a SPARK, which occurs between the electrodes of the plug.

WORKING OF SPARK PLUGS

The plug is connected to the high voltage generated by an ignition coil or magneto. As current flows from the coil, a voltage develops between the central and side electrodes. Initially no current can flow because the fuel and air in the gap is an insulator, but as the voltage rises further it begins to change the structure of the gases between the electrodes. Once the voltage exceeds the dielectric strength of the gases, the gases become ionized. The ionized gas becomes a conductor and allows current to flow across the gap. Spark plugs usually require voltage of 12,000–25,000 volts or more to "fire" properly, although it can go up to 45,000 volts. They supply higher current during the discharge process, resulting in a hotter and longer-duration spark.

HOW DO THEY WORK

They white ceramic of a spark plug acts as the insulator. It runs from the top of a plug, through the metal body to the firing end top and it is this insulator material that ensures the voltage is contained and presented from leaking.

Any escape of voltage would create a misfire or no spark at all.

This high voltage must be contained and prevented from discharging anywhere other than between the spark plug electrodes.

WHAT SORT OF TECH GOES INTO CREATING SPARK PLUGS?

Special alloys for Centre electrode material to increase Performance, service life.

Lighter compact engine configurations, valve positioning and cylinder heads.

THICKER AN INSULATOR, BETTER THE SPARK PLUG

popular spark plugs have diameter of 9mm on insulator.

WHAT ARE THE MAIN PROBLEMS WITH SPARK PLUGS?

An oily spark plug covered in carbon on the firing end

Fueling Setup or sometimes the way the vehicle is being used (stop start, not letting the spark plug get hot enough) are likely reasons.

Another cause of fouling, is poor fuel condition.

The firing must maintain an operational temperature of between 450c and 870c. Too cold and it may misfire or foul.

ARE THEY MORE OF A NECESSITY FOR A ROAD BIKE OR RACE BIKE?

Most of race plugs are now Iridium this has proved to be the way formed, and satisfies the never-ending quest for maximizing the performance

All the while withstanding the increased temperature, pressures and vibrations they are exposed to in the combustion chambers of highly stressed RACE engines.

Platinum and Iridium alloy plugs have become the choice for manufacture.

IRIDIUM Being the best material, being one of the least abundant elements.

It is chosen for its hardness, resistance to heat, oxidization and wear. it has a melting point of 2450 Degrees

A spark plug in a 4-stroke engine revving at 9000RPM will spark 75 times in a second.

A spark plug in a 2-stroke engine which utilizes ‘wasted spark’ ignition will spark 150 times a second at 9000RPM.

Service life of plugs is on an average doubled using IRIDIUM plugs in place of standard Nickel.

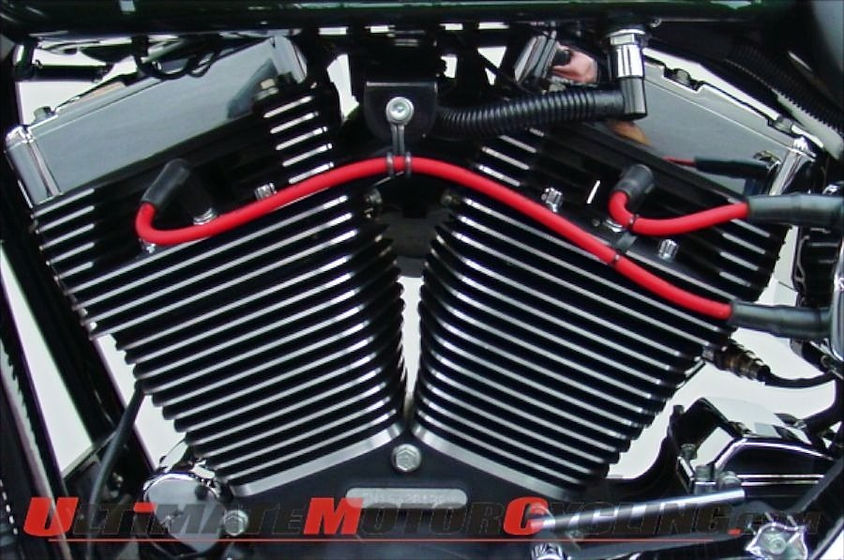

PARTS OF A SPARK PLUG

Terminal: This part is located at the top of the spark plug and is used to connect it to the ignition system. Some applications use a spade connection while others use a Snap-On connection.

Insulator: The insulator in made of porcelain. It has main two functions. The porcelain provides a mechanical support for the for the electrode and it insulates the high voltage. It also serves as an extension of the electrode for easy access.

Ribs: Because of the extended distance of the electrode to the grounded metal case, the ribs improve the electrical insulation and prevent electrical energy from leaking along the insulator.

Insulator Tip: The sintered aluminum oxide ceramic insulator is located between the metal case and the center electrode. It will withstand 600° C and 60,000 volts. The exact composition and length determines the heat range. Short insulators are cooler while longer insulators run hotter.

Seals: Seals insure that there is no leakage from the combustion chamber. It made by a multi-layer braze. Special alloys of are used to work with the metal case and the ceramic insulator.

Metal Case: Also known as a “Jacket”, its purpose is to torque the spark plug into the cylinder head. It also grounds the the spark going through the center electrode. Another duty it has is to cool the heat passing through the insulator.

Center Electrode: It is connected to the terminal through an internal wire and usually through a ceramic series resistor to reduce radio noise. The tip can made from a combination of copper, nickel-iron, chromium or precious metals. The center electrode is the hottest part of the plug which emit electrons (aka cathode). Newer longer lasting plugs now use electrodes made of yttrium, iridium, platinum, tungsten, or palladium.

Ground Electrode: The side or ground electrode is made of high nickel steel and welded to the metal case.

Spark Plug Gap: Although many people assume that you can use the plugs unchanged right out of the box is true because the plug may be used for several applications which require different gaps. A simple gap gauge is all that is needed to adjust the gap to factory specs. for your application.

CAUSES OF CARBON FOULING

Continuous low speed driving and/or short trips

Spark plug heat range too cold

Reduced compression and oil usage due to worn piston rings / cylinder walls

Over-retarded ignition timing

Air-fuel mixture too rich

Ignition system deterioration

"Indexing" of plugs upon installation involves installing the spark plug so that the open area of its gap, not shrouded by the ground electrode, faces the center of the combustion chamber rather than one of its walls. The theory holds that this will maximize the exposure of the fuel-air mixture to the spark, also ensuring that every combustion chamber is even in layout and therefore resulting in better ignition. Indexing is accomplished by marking the location of the gap on the outside of the plug, installing it, and noting the direction in which the mark faces. Then the plug is removed and washers are added to change the orientation of the tightened plug.